We have much more to do and your continued support is needed now more than ever.

Ground-Source Heat, from Lipscomb to Yale

This story is the third and final of a series that explores various types of ground heat mining and their campus applications. Also see Universities Lead the Charge to Mine the Heat Beneath our Feet, and The Heat Movers. -Ed.

The geothermal heating and cooling system installed on Lipscomb University’s new Ezell Center got a trial by fire during the scorching Tennessee summer of 2008, when temperatures topped 100 degrees on 16 days. The heat wave was no sweat for the energy efficient system. The Ezell Center, built in 2006, “was the coolest building on campus,” says Don Johnson, director of facilities at the Nashville school. “The system has performed beyond our wildest expectations.”

Hoping to lower their energy bills, cut greenhouse gas emissions and reduce maintenance costs, a growing number of colleges and universities are installing geothermal heating and cooling systems, which extract warmth from the ground in winter and sink heat into the ground in summer. Also known as ground-source heat pumps (GSHPs), the systems reduce reliance on fossil fuel power, which is prone to budget-busting price spikes due to volatile energy markets. “It allows you to set your budget for heating and cooling for 10 years or more,” says Janet Reeder, editor of Geo Outlook at Oklahoma State University.

California’s Feather River College was wracked with high energy bills through the 1990s due to antiquated electric furnaces and outdated air conditioners that ate up 65 percent of its energy budget. So the school installed a geothermal heating and cooling system in 1998 and lowered its energy costs by $50,000 the first year – big money for a small community college with a tight budget.

How does it work?

Antiquated furnaces and air conditioners are often a building’s largest energy hog and carbon emitter, which is why some schools are retrofitting old buildings with geothermal heating and cooling systems when replacing or upgrading heating, ventilation and air conditioning (HVAC) systems. Other universities such as Lipscomb are integrating GSHPs into the design of new high-performance buildings, which allows for optimal savings. Ground-source heating and cooling also appeals to historic preservationists because it eliminates the noisy and unsightly exterior air exchangers and condensers associated with conventional HVAC systems. New York’s Hamilton College decided to heat and cool its 1920s-era Skenandoa House dormitory with geothermal energy for this reason.

There are two basic GSHP designs. Colleges with ample space often build closed-loop systems that circulate water or antifreeze through a network of underground pipes, typically buried beneath an athletic field or parking lot. Universities in tight urban areas such as Harvard and Yale often choose to build deeper open-loop or “standing column” systems, which have fewer wells but drop to a depth of 1,500 feet or more and have a small above-ground footprint.

It’s not a perfect system…yet

Whatever the choice, the most important step is to hire experienced engineers to design the system so it meets the needs of the building, and reputable drillers to ensure the wells are bored to the proper depth and specifications. “The industry doesn’t get a good grade in the past for doing what’s spec-ed out,” says Thomas Downing, Yale’s senior energy engineer. “Wells must be drilled to the proper specifications or you won’t get the performance.” Before any work is done, a test should be performed to determine the ground’s thermal properties, which establishes how large a system should be built. The International Ground Source Heat Pump Association lists accredited designers and installers.

As with any new and growing technology, geothermal heating and cooling system design and installation techniques are being honed to eliminate past mistakes that caused some systems to under-perform and not deliver promised savings. At Harvard, for instance, brackish groundwater has caused unexpected corrosion and required frequent replacement of filters and other maintenance issues. Open-loop systems, which draw groundwater up from great depths, are particularly susceptible to local geological quirks. Some underground aquifers and well fields tend to heat up in summer as heat from buildings is dumped underground, diminishing cooling performance.

Ground-source heating does not eliminate a building’s energy use because electricity is required to power pumps that move the water and fans that move hot or cool air through a building. Some schools install solar panels to offset this electricity use. However, the life-cycle savings and return on investment typically make GSHPs worth the higher up-front expense, which is due to the cost of drilling and burying pipes.

Your mileage may vary

The payback and savings vary with every installation due to differences in system design, local geology (the ground’s thermal properties differ from one location to the next), local electric and natural gas rates, local climate and other factors. Lipscomb, for instance, estimates a five- to seven-year return on investment but spiking energy prices could cut that to as little as 16 months. New Jersey’s Richard Stockton College estimates its system paid for itself in four-and-a-half to seven-and-a-half years.

The longevity of GSHPs is projected at 20 to 30 years or more. It could be a decade or more before the ultimate longevity of various systems is known. Here are a few hot campus projects and their cool (and lukewarm) aspects:

Lipscomb University, Nashville, TN

Beta: A closed-loop system of 144 wells 300 feet deep heat and cool the 77,000-square-foot Ezell Center academic building.

Cost: $950,000, with $500,000 covered by U.S. Department of Energy grant.

Why it’s Hot: 65 percent reduction in energy use compared to a baseline building. Maintenance calls on the Ezell Center are a fraction of those for other campus buildings, saving money on manpower.

Why it’s Cool: Spiking energy prices could lower the return on investment to less than a year-and-a-half.

Why it’s Lukewarm: In-room heat pumps were mounted above the ceiling. “That was our only mistake,” Johnson says. “They are hard to access when we need to service them.”

The Scoop: The Ezell system was so successful that the school added two more GSHPs in 2008-a $750,000 retrofit of the Health Sciences building and a $68,000 system for a cluster of small residence halls. The loop fields were drilled to 500 feet-a depth that provides twice as much cooling “for less than twice the cost,” Johnson says.

Yale University, New Haven, CT

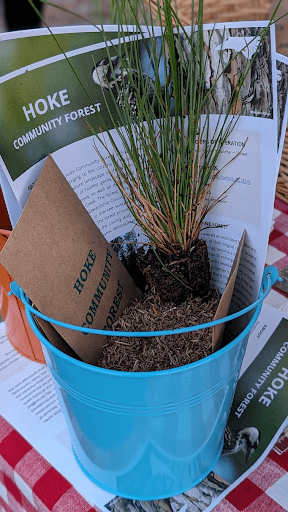

Beta: Four 1,500-foot open-loop (or standing column) wells will heat and cool 50,000-square-foot Kroon Hall, which will house the Yale School of Forestry and Environmental Studies when it opens in early 2009.

Cost: Unavailable.

Why it’s Hot: Will provide 100 percent of the building’s cooling and 25 percent of heating.

Why it’s Cool: Kroon Building is expected to attain LEED Platinum certification–part of Yale’s effort to cut greenhouse gas emissions 43 percent while simultaneously growing its campus.

The Scoop: Yale chose standing column wells because of limited space. It hired an experienced geotechnical firm, Haley and Aldrich, to design the system and dug a test well “to figure out the well’s precise geothermal conditions,” says Downing. “That’s essential for anyone doing a standing column.”

Richard Stockton College, Pomona, N.J.

Beta: Closed-loop system of 400 wells with 64 miles of underground pipe buried to a depth of 425 feet that heats and cools 400,000 square feet of classrooms, offices and labs.

Cost: $4.1 million, most of which was covered by utility rebates and state grants.

Hot: $400,000 in annual fuel and maintenance savings, 25 percent reduction in electricity, 70 percent reduction in natural gas, return on investment of 4.6 to 7.5 years, and a 17 percent reduction in campus greenhouse gas emissions.

Cool: International delegations from Asia and Europe have visited to learn about the system, the largest of its kind when installed in 1994.

Lukewarm: The school must monitor aquifer temperatures regularly to avoid “heat creep,” the tendency of GSHPs to warm the ground over time and diminish performance. Soil and aquifer microbiota are also analyzed regularly to ensure dumped heat does not encourage pathogen growth.

The Scoop: The college is now installing an open-loop Aquifer Thermal Energy Storage system. “This is the next generation of geothermal,” says physics professor Lynn Stiles. It will pump 55-degree water out of an aquifer in winter and circulate it through a cooling tower, chilling it to 40 degrees. In summer, the water will be pumped up to chill buildings not connected to the older geothermal system.

Hamilton College, Clinton N.Y.

Beta: Completed in 2004, the system has 16 wells buried to a depth of 405 feet. A water-to-water radiant system warms the slab of Skenandoa House, a 21,000-squre-foot dormitory built in the 1920s, while thermostat-controlled water-to-air heat pumps in dorm rooms allow occupants to adjust temperatures to their individual preference.

Cost: $80,000 (a $48,000 state grant made the out-of-pocket expense $32,000).

Hot: 60 percent decrease in energy use, $11,000 annual savings and a three-year return on investment. Life-cycle savings should be approximately $330,000, based on the system’s projected 30-year lifespan.

Cool: The GSHP system preserves the historic character of the building because it allows for the elimination of ugly exterior HVAC equipment.

Lukewarm: Heating is gradual and does not provide the blast of hot air some students are accustomed to. “It’s an oxymoron, but geothermal heat is cool heat. You have to get used to it,” says Steve Bellona, associate vice president for facilities and planning.

The Scoop: Hamilton hired the most experienced local designer, a crucial step for anyone installing a GSHP. “You don’t just get some engineer off the street,” Bellona says. The system was tested to the max its first winter, when temperatures dipped below zero for two weeks. “Skenandoa House was the only building on campus that didn’t have any complaints,” Bellona says.

Harvard University, Cambridge, MA.

Beta: Fifteen open-loop wells drilled to a depth of 1,500 feet and five wells of 450 to 850 feet provide partial heating and cooling to multiple buildings containing classrooms, labs, student residences and administrative offices. The university is now building its first closed-loop system-88 loops 500 feet deep–on the 27,000-square-foot Weld Hill Research and Administration Building.

Cost: Unavailable, estimated at $150 per foot of drilling.

Hot: Estimated 40 percent greater efficiency than conventional HVAC.

Cool: The Blackstone South building, Harvard’s first GSHP project, attained a LEED Platinum rating when opened in 2003.

Lukewarm: Too few meters were installed on Blackstone South, making it difficult to monitor efficiency. The school has since installed more meters so it can calculate savings. Performance of the open-loop wells has also been diminished due to the tendency of the aquifers to heat up in summer, providing less cooling capacity and diminishing savings. The open-loop systems are also prone to corrosion due to brackish groundwater, and minerals in the water clog filters, necessitating unanticipated maintenance.

The Scoop: Like Yale, Harvard chose open-loop wells because of limited space. “In a city, there is no space for a large well field,” says Tony Ragucci, associate director of facility maintenance operations. Ragucci and his colleagues have assembled a helpful presentation that outlines lessons learned about operating open-loop systems, an essential read for anyone considering an open-loop installation.

Feather River College, Quincy, CA

Beta: One vertical closed-loop system of 56 wells, 115 to 250 feet deep; and two horizontal closed-loop systems with a total of 192 pipes buried in five-foot deep trenches up to 295 feet long.

Cost: $512,000, $218,000 more than the price of installing less-efficient air-source heat pumps.

Hot: Anticipated five-year return on investment.

Cool: As a demonstration project, the GeoExchange system received $35,000 from the Geothermal Heat Pump Consortium and $300,000 from the state. Princeton Development Corporation, the designer, loaned the school $120,000.

Lukewarm: Mud, granite and other unpredictable geology necessitated changing plans to avoid larger-than-expected drilling costs. Instead of 250 feet, some loops were installed to 100 feet. Typically, deeper loop fields provide more heating and cooling.

The Scoop: Feather River provides a lesson in creative financing for other small community colleges with limited funds. Administrators arranged a lease agreement with Princeton Development Corp. to repay the company with proceeds from energy savings, allowing the school to put no money down.

Wilson Community College, Wilson, N.C.

Beta: Built to heat and cool a new 16,000-foot Student Center, the closed-loop system will use novel EarthLinked technology that circulates refrigerant through copper pipes, replacing the typical plastic water pipes.

Cost: Unavailable.

Hot: Anticipated 15 percent reduction in energy use compared to a baseline building.

Cool: The half-inch copper pipes were buried at a 45-degree angle instead of vertically. “You get more pipe-run for a given depth of drilling,” says project engineer Chuck Ladd of Williard Ferm Architects.

Lukewarm: A sacrificial anode system has been installed to prevent corrosion on the copper pipes. The long-term performance of this corrosion-fighting technique remains to be seen and could dramatically affect life-cycle savings.

The Scoop: In a typical GSHP system water is pumped to the heat pumps, where refrigerant exchanges heat with the water. By contrast, this system has no water pumps. A compressor pushes refrigerant through the loop field, eliminating the need to expend energy pushing large quantities of water. Activated this fall, the system “appears to be performing to our requirements,” Ladd says.