We have much more to do and your continued support is needed now more than ever.

Campuses Try Not to Waste the Waste

This idyllic setting is something at least one university professor would like to become a reality. Using anaerobic digestion, which is an oxygen-free method of composting organic matter while also capturing the methane created during its decay, students could experience a new wave of “eco-dining,” a term Dr. Ann Wilkie likes to use to describe this imaginary dining hall.

Dr. Wilkie is an associate professor of environmental microbiology at the University of Florida’s Institute of Food and Agricultural Sciences, and in 2008 she assisted an undergraduate student, Ryan Graunke, with an award-winning biogas study involving one of the school’s dining halls and an anaerobic digester.

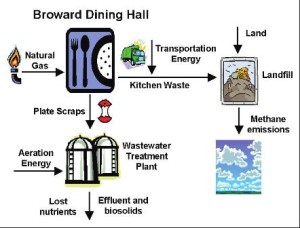

“The [dining hall] was an interesting idea for us to look at,” explains Dr. Wilkie, “because it was a way to look at sustainability at the local level.” In the study, Graunke measured the food waste generated from UF’s Broward Dining Hall and then analyzed its potential biogas yield through anaerobic digestion.

The study found that the 1,250+ students who ate at Broward Dining Hall every day were discarding just over 4,000 pounds of food waste each week. If all of that food was composted in an anaerobic digester, the biogas created would supplement, on average, 17.8 percent of the dining hall’s natural gas needs, as well as save the school about $3,000 annually in energy costs (plus savings from not paying to haul the waste to a landfill). Additionally, a nutrient-rich, liquid effluent would be created that can be used in place of chemical fertilizers for growing foods consumed by the students.

“Waste is not waste until you waste it,” says Dr. Wilkie. “And all food waste materials, liquid or solid, can be processed with an anaerobic digester.” UF has since been working with ARAMARK, an international food services company, on making their anaerobic digester applicable to other university campuses.

In the world of composting, anaerobic digestion sets itself apart from other methods of composting because of its dual-purpose results. Whereas more mainstream compost methods, such as windrow piles, vermicomposting and in-vessel aerobic (with-oxygen) digesters, succeed in keeping food waste out of landfills and create nutrient-rich soil amendments, anaerobic digesters go a step further by also producing a renewable, methane-based biogas that can be used in the same ways as natural gas.

Currently, in the United States, anaerobic digesters are primarily being used by farmers to process animal manure and by municipal wastewater treatment facilities to manage wastewater solids. However, one 2006 EPA-funded study suggests that using an anaerobic digester to process food waste can yield up to three and a half times more biogas than wastewater solids.

Another professor who has worked to further stretch the potential for anaerobic digesters is Dr. Ruihong Zhang, professor of bioenvironmental engineering at the University of California-Davis. Dr. Zhang developed an anaerobic digester that not only captures methane from food waste; it also captures hydrogen.

What started as a research demonstration composting project on the UC-Davis campus, processing about eight tons of food waste each week from high-end restaurants in the Bay area, the Biogas Energy Project has turned into a very large endeavor.

“We now process food waste from restaurants in San Francisco,” explains Dr. Zhang, “food waste from the University cafeterias and student housing, and food waste from the Campbell’s Soup plant in Sacramento.”

UC-Davis has only been working with the Campbell’s Soup plant since June 2008, but in that time the school has already processed over 200 tons of the plant’s food production waste, creating enough energy to power 2,000 California homes for a day. And given that Californians send 5.9 million tons of food waste to landfills each year, making it the state’s single largest category of municipal solid waste, UC-Davis has access to many more “mounds” of research materials.

Perhaps with this blending of the ancient science of composting and modern-day biogas technologies, students will one day find themselves in that futuristic dining hall being able to surf the internet, text message their friends and listen to music with electronics run by hydrogen fuel cells, which will have been powered by last month’s lunch special.